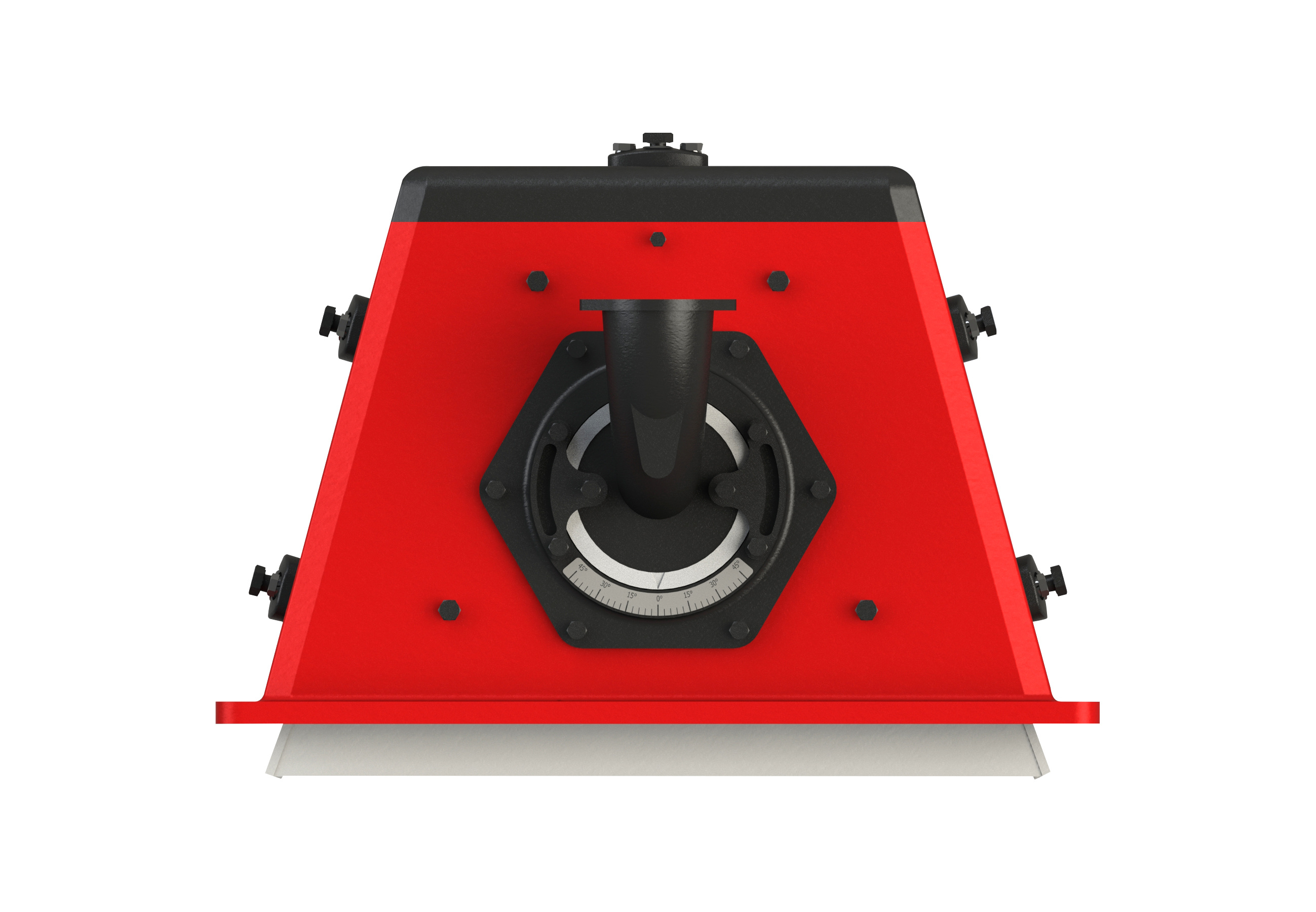

High chromium lining plate

key word:

High chromium lining plate

The high chromium lining plate is mainly subjected to impact wear, fatigue wear, and abrasive wear, so high chromium cast iron is used as the material for the blades. However, high chromium cast iron is brittle and prone to fracture and fragmentation under high impact, requiring corresponding heat treatment to improve its performance.

High chromium alloy casting grinding balls are applied in metallurgical mines, mineral processing plants, cement plants, and new building materials fields, serving as grinding materials. The ores, limestone, coal, and other materials in the ball mill are crushed and ground through self grinding and mutual impact friction.

Quality control

Temperature measurement of molten iron

impact testing machine

Chemical Analysis Laboratory 0

Dimensional inspection of semi-finished products

Previous page

Next page

Related products

The robot arm is the most widely used automated mechanical device in the field of robot technology.

The high chromium lining plate is mainly subjected to impact wear, fatigue wear, and abrasive wear, so high chromium cast iron is used as the material for the blades. However, high chromium cast iron is brittle and prone to fracture and fragmentation under high impact, requiring corresponding heat treatment to improve its performance.

The high chromium lining plate is mainly subjected to impact wear, fatigue wear, and abrasive wear, so high chromium cast iron is used as the material for the blades. However, high chromium cast iron is brittle and prone to fracture and fragmentation under high impact, requiring corresponding heat treatment to improve its performance.

The double discs in the shot blaster are riveted together to form the impeller body

MESSAGE

Timely contact with our team and would be happy to assist you

*Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible