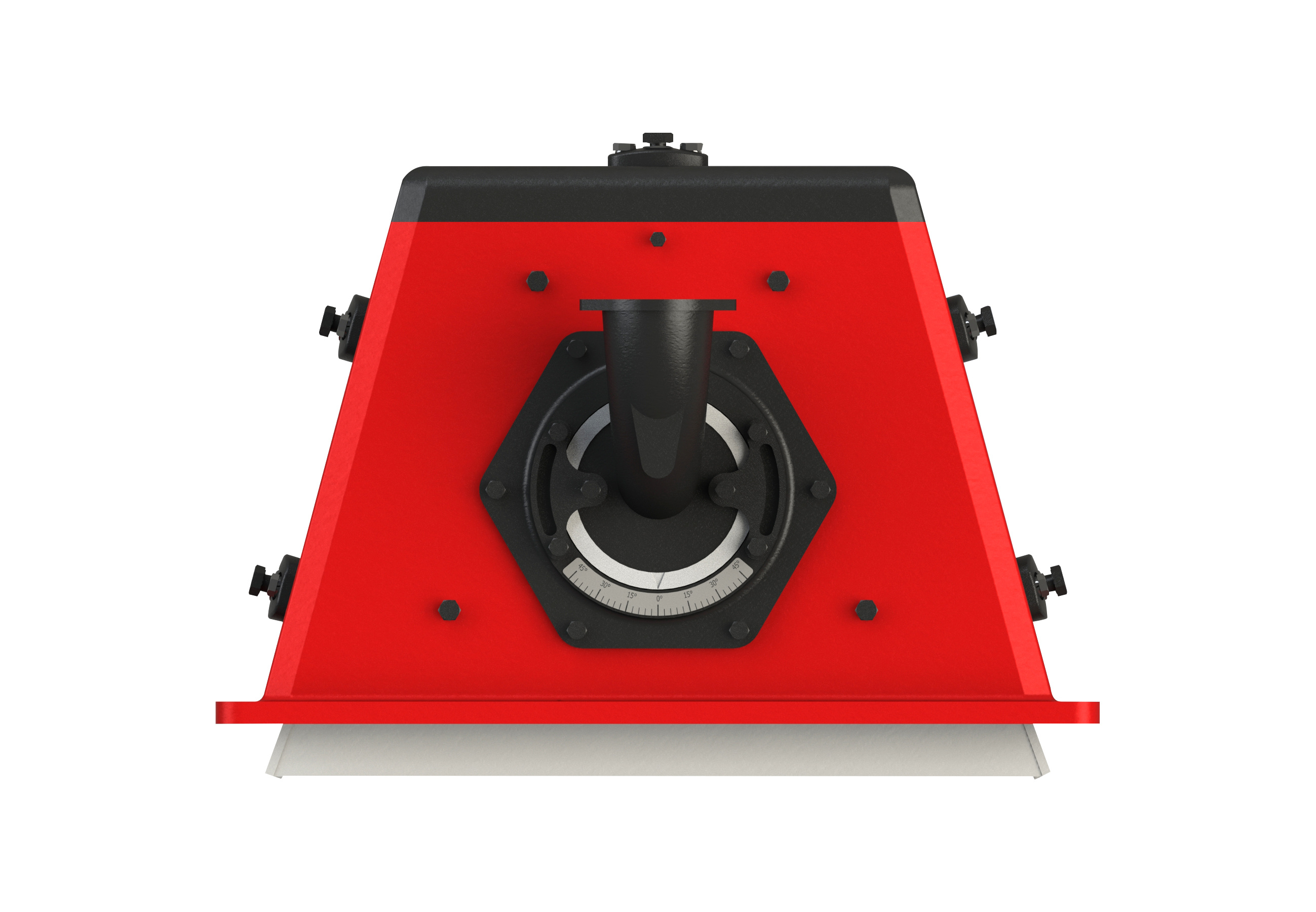

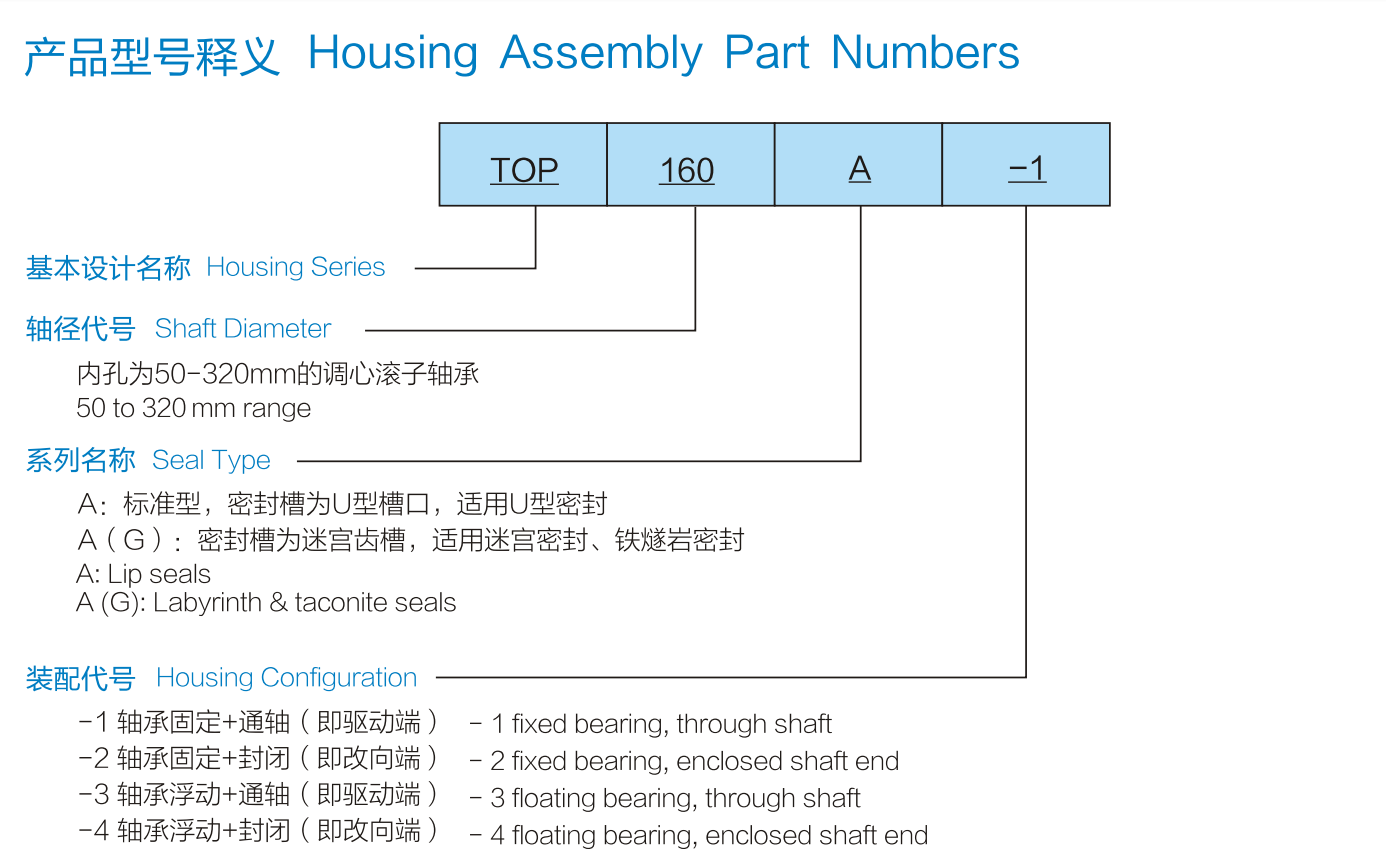

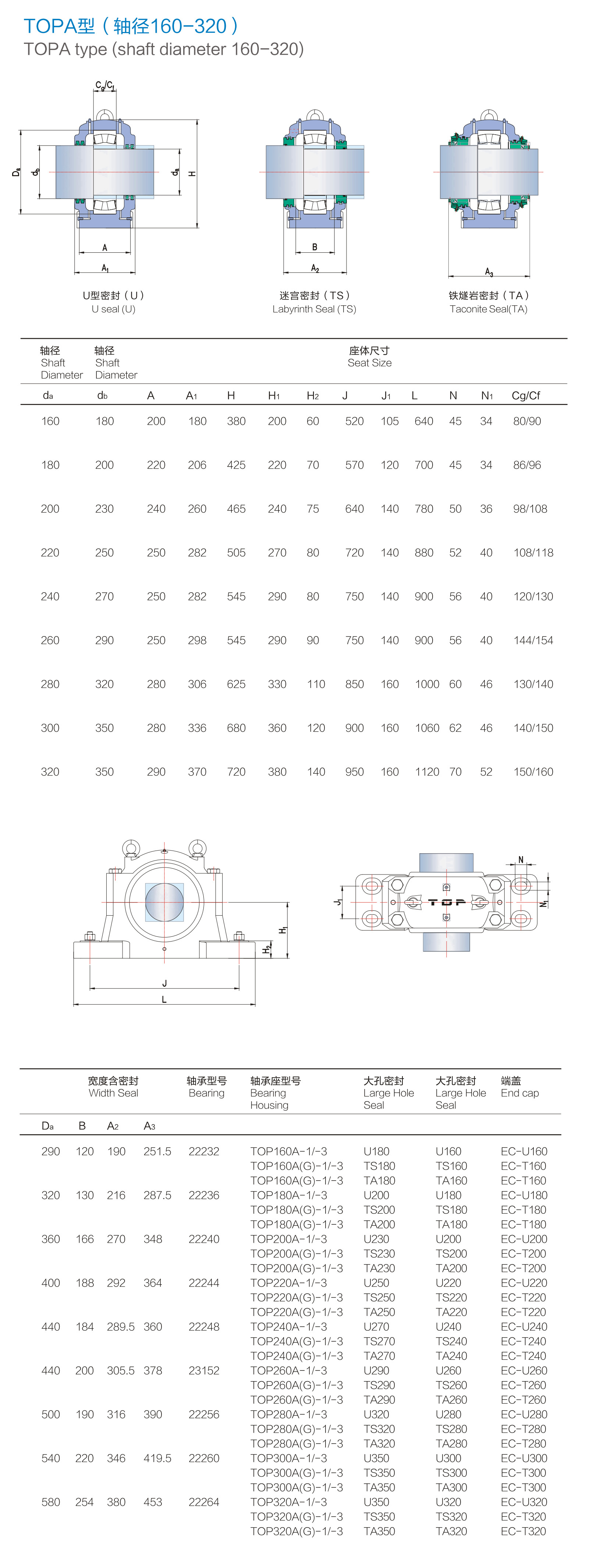

TOPA型剖分式轴承座适用干内孔直径为50-320的直孔调心滚子轴承,是以传统DTII型轴承座的安装尺寸为基础进行改型设计,座体采用剖分式上下部分的结构,去除了传统轴承座心盖、透盖、骨架宓封的繁琐的安装过程,并且拆卸方便,座体的底部采用进行了优化设计,在保证轴承座强度的同时,减少的座体重量,降低材料成本,具有良好的散热性,便干降低轴承工作温度,延长补充润滑的间隔时间,座体材料使用能承受较大载荷的优质灰铸铁与球墨铸铁,整体外形精美,在设计结构、质量和经济上都是客户的首要选择。

Quality control

Temperature measurement of molten iron

impact testing machine

Chemical Analysis Laboratory 0

Dimensional inspection of semi-finished products

Related products

The robot arm is the most widely used automated mechanical device in the field of robot technology.

The high chromium lining plate is mainly subjected to impact wear, fatigue wear, and abrasive wear, so high chromium cast iron is used as the material for the blades. However, high chromium cast iron is brittle and prone to fracture and fragmentation under high impact, requiring corresponding heat treatment to improve its performance.

The high chromium lining plate is mainly subjected to impact wear, fatigue wear, and abrasive wear, so high chromium cast iron is used as the material for the blades. However, high chromium cast iron is brittle and prone to fracture and fragmentation under high impact, requiring corresponding heat treatment to improve its performance.

The double discs in the shot blaster are riveted together to form the impeller body

MESSAGE

Timely contact with our team and would be happy to assist you

*Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible